Low-volume manufacturing saves you money

Most people think it’s obvious that manufacturing costs per

unit will go down as volumes go up. So if you want to make

cheap parts, you should make more of them, right? Not

necessarily. If you’re going to mass-produce parts –

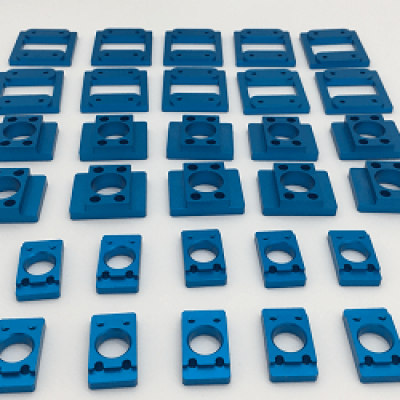

especially for Components of Die&Stamping mold or injection molding –

then you must make a larger investment in more expensive

tool steel, which in turn needs to be hardened and

heat-treated more carefully to withstand the rigors of

large-scale production.

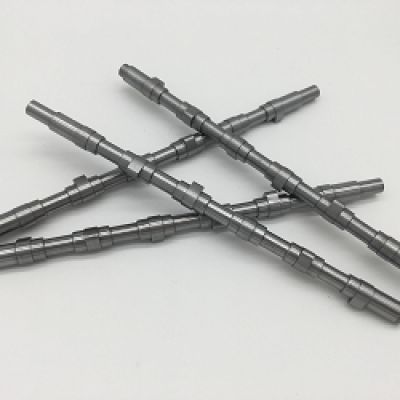

With this in mind, low volume manufacturing up to 100K pcs

may be a great way for you to avoid a large investment while

still producing high-quality parts. If the tool steel

doesn’t need to be so durable then it will be more

economical for you to purchase and faster for us to heat

treat and machine. And, if your tool wears out during

production and you need to have another one made, we do that

at no extra charge!

By comparison, when a factory is set up for large-scale

production it carries a massive inventory of raw materials

and equipment. To cover their investment, they usually ask

you to place a large minimum order quantity. But a

specialist in low-volume manufacturing doesn’t carry the

same amount of overhead so we can process orders faster and

more economically without demanding any minimum order.

At Reliable precision, we will be there to help you along every

step of the way, from the initial product design review and

quotation to quality inspection of your newly manufactured

parts. In addition to specializing in prototyping and mass

production, we are also a specialist when it comes to

low-volume manufacturing. Contact our expert team today to

get a free project review and initial quotation. If you need

a prototype to verify your design first, please review our

rapid prototyping

services.